Inspecting Ductwork in Residential Homes

This article talks about the ductwork found in a home and identifies the components along with how the ductwork should be installed.

According to NHRAW (North American Heating, Refrigeration & Air-conditioning Wholesalers) the goals for any finished duct system are:

- The system is reasonably air-tight.

- The system is noise/vibration free.

- The system minimizes resistance to air flow.

- The system is economical.

Keep each of the 4 goals in mind as you begin the inspection of your duct system.

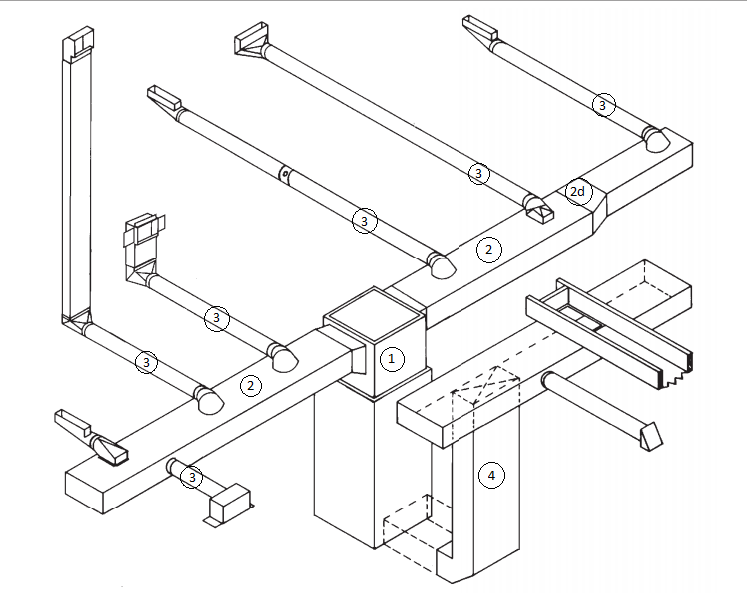

- The plenum is the central collecting chamber of the conditioned fresh air leaving the furnace

- The plenum is the first stage of the ductwork system.

- The plenum is attached to the supply air opening of the furnace.

- After the plenum has been assembled the plenum must now be secured to the furnace.

- On an upflow furnace the plenum is secured to the top of the furnace. (the opposite for downflow)

- The installer simply places the plenum over the supply air opening of the furnace and secures the plenum with sheet metal screws along the bottom edges.

- Trunk lines should only come off the sides of the plenum rather than the top.

- Trunk Lines must come off the plenum at least 6” below the top of the plenum in order to maximize air mixing.

- The main trunk line is the central distribution source for conditioned air leaving the plenum. (This type of system is sometimes referred to as the extended plenum system).

- The main trunk line is attached to the plenum and extends the entire length of the home.

- In most installations, the furnace will be centrally located with the main trunk line extending in both directions.

- The main trunk line may run above the ceiling or below the floor.

- Rule of Thumb: The width required for a section of rectangular duct is determined by counting the number of outlets that section will be required to serve. Multiply the outlet number by two and then add two.

- This total will be the width in inches required to properly heat/cool the room while maintaining a constant airflow pressure.

- Note: The above calculation is used when installing 6” around pipe (standard) off the main trunk line.

- Example: A section of duct will serve 5 supply air outlets.

Six-inch pipe will be used for branch runs.

The width of the duct should be: (5 supply air outlets) x 2 = 10

10 + 2 = 12

This section would require a 12” x 8” piece of duct.

(8” is standard rectangular duct height.)

- A transition/reducer is installed to maintain a balanced pressurized air flow system. When a take-off or take-offs are installed on a section of the main trunk-line, the airflow pressure at that point is thus reduced requiring a smaller amount of duct to distribute the conditioned air.

- Branch Runs are used to distribute the conditioned air from the main trunk line to the predetermined supply air outlets in the floor or wall.

- The Branch Run is attached to the main trunk-lines and is routed to the designated supply outlet.

- Colder Climates The supply air register should be located on the floor near an outside wall, preferably under a window in order to minimize drafting.

- Warm Climates The supply air register should be located on the ceiling, for optimum air conditioning performance.

- The Branch Run is attached to the main trunk-lines and is routed to the designated supply outlet.

- Return Air – For every cubic foot of air the system delivers to the home, an equal amount of air must be returned to the furnace. The return air system is designed to redirect air that has been circulated throughout the home, back to the furnace where it can be reconditioned and delivered back into the supply air.

- Wall studs and floor joists are utilized in place of duct for the return air system.

- The air is drawn through the return air grille into the wall cavity down to the floor joist.

- Joist panning is used to seal off the underside of the floor joists where the return air is directed to a section of rectangular duct.

(Joist panning is cut in 3’ lengths and in widths to space across wood floor joists.)

(An adjustable joist pan header is used to seal off the end of a joist.) - Residential codes permit joist and panning installations as return air pathways only. These pathways should not be used for supply air.

- Many of the same components and principles used in the supply side distribution can be utilized in the return air installation.

- An effective location for the return air inlets will ensure maximum efficiencies. These are usually located on inside walls.

- Wall studs and floor joists are utilized in place of duct for the return air system.

Charles Bellefontaine CMI, CPI, ACI

June 17, 2018

Air-Conditioning, Heating

No Comment